How Celette’s Tracking Gauge Module is Reinventing Structural Measurement for the Collision Repair Industry

From Manual to Smart

In the modern collision repair landscape, precision is no longer optional, it’s essential. As vehicles become more complex, with advanced materials, tighter tolerances, and ADAS systems integrated into nearly every model, body shops are under increasing pressure to repair vehicles accurately and to document their work in a transparent, standardized way.

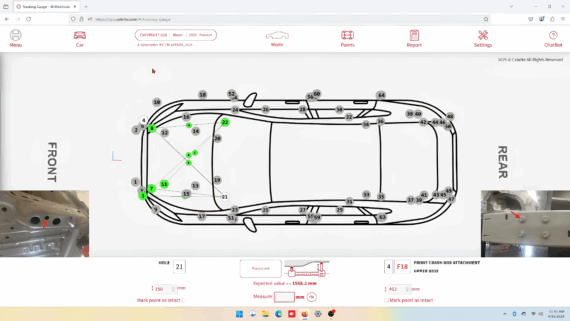

At Celette, we’ve always believed that measurement is the foundation of quality repair. But today, we’ve taken that belief a step further, with the launch of our Tracking Gauge module inside the Celette AI Webtools platform. This universal digital solution transforms how body shops perform structural measurements, record data, and communicate with insurers, all while staying compatible with both mechanical and connected (digital) tracking gauges.

This article explores how the Tracking Gauge software works, who it’s designed for, and why it represents a major step forward in modernizing collision repair.

Why Measurement Still Matters—More Than Ever

Many in the industry tend to think of measurement as a task reserved for only the most severe structural repairs. In reality, precise and documented measurements are becoming necessary even for seemingly minor collisions.

Here’s why:

- Most OEM repair procedures now require verified measurement steps.

- ADAS-equipped vehicles require close tolerances for sensor mountings to ensure aiming and reintroduction/reinitialization calibrations can be performed for proper functionality.

- Liability protection demands traceability by documentation of every step taken in a repair.

- Inaccurate structural alignment can compromise occupant safety, drivability, roadworthiness and longevity of the vehicle even when the exterior looks perfect.

That’s where Celette’s Tracking Gauge system enters the picture, with a solution that simplifies structural measurement while enhancing its reliability and transparency.

What is the Tracking Gauge Module?

The Tracking Gauge module is a software solution built into Celette AI Webtools, our universal digital platform for vehicle repair. It is designed to work with:

- Mechanical tracking gauges (traditional systems using analog rods)

- Connected tracking gauges (digital tools transmitting data wirelessly to the software)

Even in mechanical mode, the software supports Z-axis height estimations, providing a more complete structural view without the need for full digital equipment.

How It Works: Simple Workflow, Powerful Results

- Vehicle Selection The technician selects the make, model, and year of the vehicle. Celette AI Webtools pulls up all structural data from our certified database.

- Point Mapping The software displays OEM-approved reference points, tolerances, and visual 3D views.

- Measurement Capture Measurements are input manually or transmitted automatically. Z-axis estimation is included, even when using mechanical tools.

- Real-Time Comparison Deviations from OEM specs are displayed using color-coded indicators (green/yellow/red).

- Repair Strategy Support The system guides the technician on repair or replacement needs.

- Insurance Report Generation A professional PDF report is produced with measurements, technician ID, VIN, shop info, and comments.

Compatible with Any Workshop Setup

Whether you’re equipped with legacy tools or cutting-edge digital systems, this software brings the same level of digital intelligence to your shop. It’s perfect for:

Whether you’re equipped with legacy tools or cutting-edge digital systems, this software brings the same level of digital intelligence to your shop. It’s perfect for:

- OEM-certified body shops

- Independent repair centers

- Insurance-approved networks

- Emerging market workshops

A System That Benefits Everyone

- Technicians gain confidence and speed with visual guidance

- Managers get better traceability and billing support

- Insurers receive verified, tamper-proof data

- Customers benefit from safer, certified repairs

Z-Axis Estimation, Even in Manual Mode

One unique capability: even with a mechanical gauge, the Tracking Gauge module can estimate vertical deviation (Z-axis). This gives shops more insight into damage depth, critical for modern structural repairs, without requiring full 3D measurement tools.

Video Demonstrations

See the system in action:

- Celette Tracking Gauge – Demo Video 1

- Celette AI Webtools – Video Studio (for internal view or access through your channel)

Powered by Celette AI Webtools

Our platform brings together multiple repair tools and digital modules in one place. Tracking Gauge connects seamlessly with:

- Bench & jig setup assistance

- Repair strategy generation

- 3D documentation tools

- Technician training modules

Explore it now at: 🌐 www.celette.com 🌐 www.collisionrepair.ai