Celette Reinvented

From Dedicated and Precision Jigs to Universal AI Solutions

For decades, Celette was known worldwide as the gold standard in collision repair equipment, particularly for its dedicated jigs, precisely engineered for each car model. These mechanical jigs, often manufactured in steel, became synonymous with structural accuracy, OEM compliance, and long-term reliability, especially for premium and complex vehicles.

For decades, Celette was known worldwide as the gold standard in collision repair equipment, particularly for its dedicated jigs, precisely engineered for each car model. These mechanical jigs, often manufactured in steel, became synonymous with structural accuracy, OEM compliance, and long-term reliability, especially for premium and complex vehicles.

This mechanical DNA remains a core part of Celette’s business. It reflects the company’s heritage, deep engineering expertise, and long-standing partnerships with OEMs. However, the evolution of the automotive industry — marked by electric vehicles, ADAS, modular platforms, and lightweight materials — demanded a new strategic direction. Vehicles now change faster, platforms are more diverse, and body shops are under pressure to work faster, smarter, and more cost-effectively.

A Strategic Shift to Hybridization

Starting in 2016, Celette initiated a profound transformation, not by abandoning its roots, but by building a hybrid company model : one that maintains its core mechanical expertise while investing heavily in universal, intelligent, and accessible repair solutions. This new model was guided by three core principles:

- Simplify tools and workflows for body shops facing complex repairs.

- Support all vehicles, not just a few models, with a flexible approach.

- Leverage digital and AI technologies to reduce time, cost, and error in the repair process.

From Dedicated to Universal Repair Platforms

Celette began developing universal systems that could adapt to multiple vehicles with minimal configuration. The result was a new generation of affordable, flexible benches and positioning tools, designed not for perfection at the micron scale, but for everyday repairs that still require precision and compliance.

Celette began developing universal systems that could adapt to multiple vehicles with minimal configuration. The result was a new generation of affordable, flexible benches and positioning tools, designed not for perfection at the micron scale, but for everyday repairs that still require precision and compliance.

Universal jig, mechanical tools such as the Cameleon, or electronic measuring systems such as the Eagle, and the NAJA now enable technicians to repair most vehicles without needing to stock hundreds of model-specific jigs. These systems can be quickly set up, adjusted, and reused, bringing agility to workshops that previously could not justify the cost or space of traditional jig systems.

This approach opened Celette to new markets, including independent body shops, insurance-recommended networks, and emerging markets where affordability and versatility matter more than factory-level perfection.

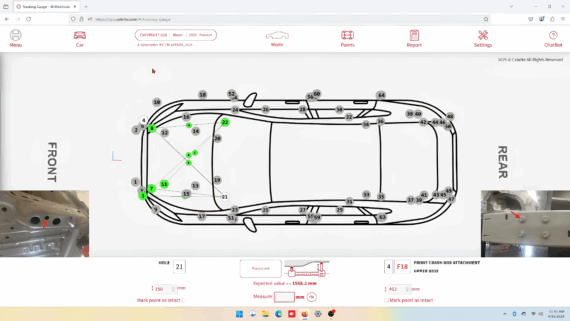

AI Webtools: The Digital Backbone

To unify this hybrid model, Celette developed the Celette AI Webtools — a universal digital platform that connects technicians to the largest vehicle repair database in the industry. This cloud-based software offers:

- Access to real-time vehicle data.

- Repair instructions adapted to the chosen system (bench, jig, or universal).

- Dynamic setup assistance.

- A modular and subscription-based pricing model.

Most importantly, it allows any repairer, anywhere, to repair any model — with or without Celette’s physical tools — by giving them digital access to vehicle-specific strategies and measurements. It’s a revolutionary shift: from selling equipment alone, to selling capability and knowledge through software.

Maintaining Quality, Expanding Access

This transformation did not dilute Celette’s standards. The company continues to:

- Work with OEMs on dedicated solutions.

- Manufacture high-precision jigs for complex structures (EVs, aluminum frames, high-strength steel).

- Offer certification support and training for high-end repair centers.

But it now balances that high-end segment with accessible, scalable solutions for a much wider range of users. Whether a shop is repairing a luxury EV or a mass-market SUV, Celette offers a suitable solution at the right price point.

Key Successes Since the Shift

- AI Webtools adoption in over 50 countries, powering both Celette and non-Celette workshop ecosystems.

- Composite and aluminum tool development, improving ergonomics, reducing costs, and adapting to new vehicle materials.

- 3D printing R&D to reduce time-to-market for new jigs and components.

- Increased OEM approvals for hybrid solutions.

- A network of global service hubs, ensuring that universal doesn’t mean unsupported.

Celette is no longer just a mechanical equipment provider. It is a hybrid technology company, offering a spectrum of solutions, from dedicated OEM tools to smart, digital, and affordable universal repair systems using AI solutions.

By doing so, Celette is not only preserving its leadership — it is expanding it, reshaping body repair worldwide by making precision and compliance available to all, not just a few.

This transformation is ongoing, driven by our belief that AI, data, and modularity are not just trends — they are the future of collision repair.